Porsche 917/10 Engine Tear Down

Porsche 917/10 Engine Teardown.

The Porsche 917 engine is a marvel of engineering wrapped together in a tidy mechanical package. Once you tear down an engine and start to see all of the gears that drive the engine and its camshafts, fan drive, etc., you start to understand why it has its signature mechanical sounds.

Canepa has the ability to rebuild Porsche 917 engines in house, whether it be for a 917K or a Porsche 917/10, naturally aspirated or turbocharged. One of our engine builders learned alongside Gustav Nietsche, one of Porsche’s factory 917 engine builders in the early 1970s. He has built and rebuilt over 80 complete Porsche 917 engines in his career, and continues to do so. Working alongside Gustav, our engine builder was able to learn the craft and subtle nuances of these fantastic engines and now can tear down and rebuild these monster motors, which is an approximately 450 hour job (including restoration time of all parts).

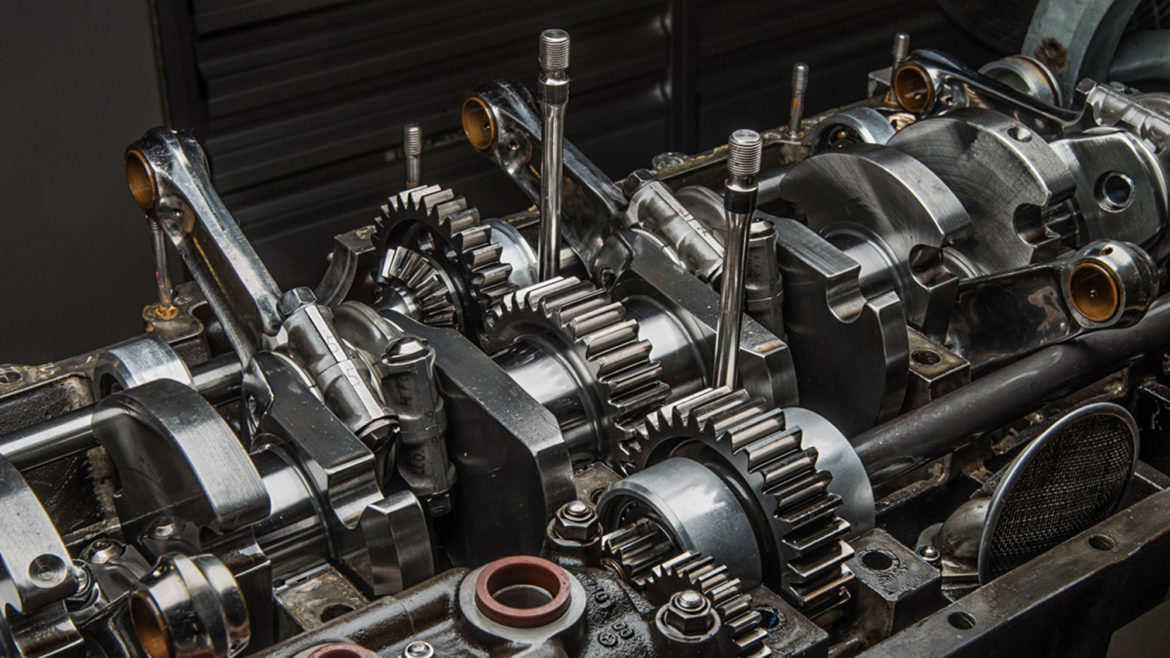

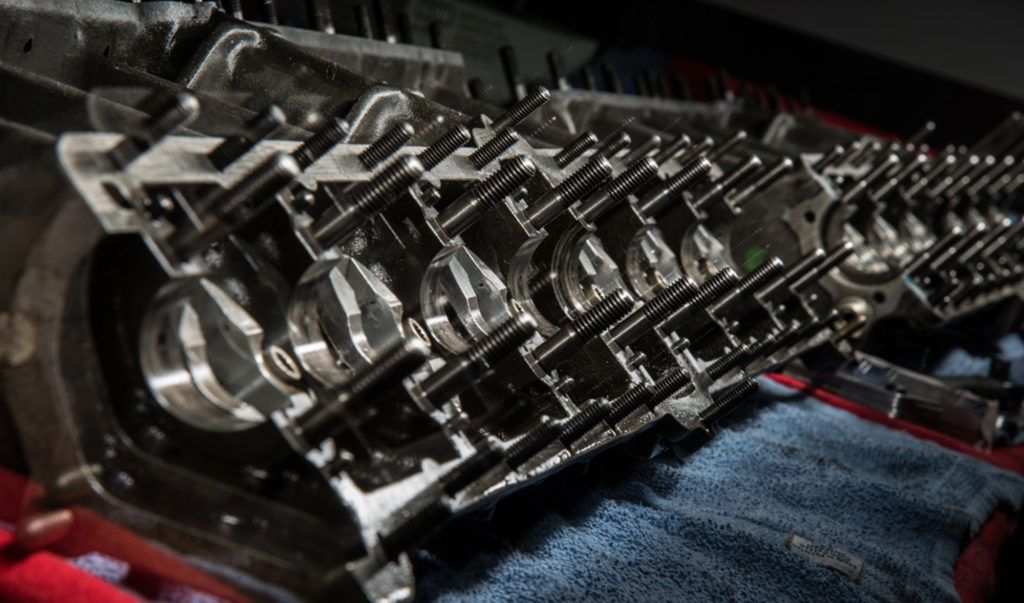

Image 1: Initial teardown. Here the camshafts are exposed and are in full view. Notice the gear in the middle of both of the camshafts, which is designed to drive the camshafts from the center of the crankshaft.

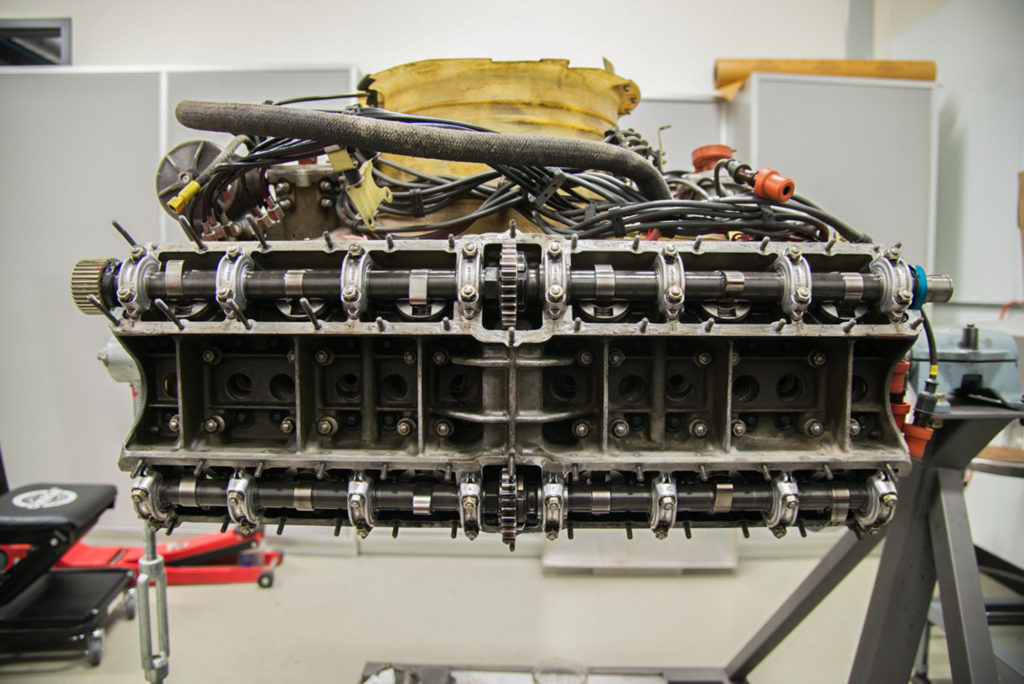

Image 2: Engine case is separated. The engine case is made of magnesium. In full view is the rotating assembly, crankshaft and all 12 of the titanium connecting rods. Here you’ll notice that power is taken off the crankshaft at two points, the top intermediate shaft and the lower output shaft. The upper intermediate shaft is responsible for driving the twin distributors as well as the alternator (and is used when setting the timing of the engine). You can also see the hole at the top of the case where there is a gear. This connects to the fan drive which spins proportionally to how quickly the engine is spinning. The lower (and shorter) output shaft is the sole power takeoff for the rear wheels. All power, whether it be 500hp naturally aspirated to 1,500+ twin turbocharged horsepower, courses through this single shaft. Depending on the application, the lower intermediate shaft could be titanium or steel. The bottom left is the gear-driven oil pump that also takes power off of the crankshaft.

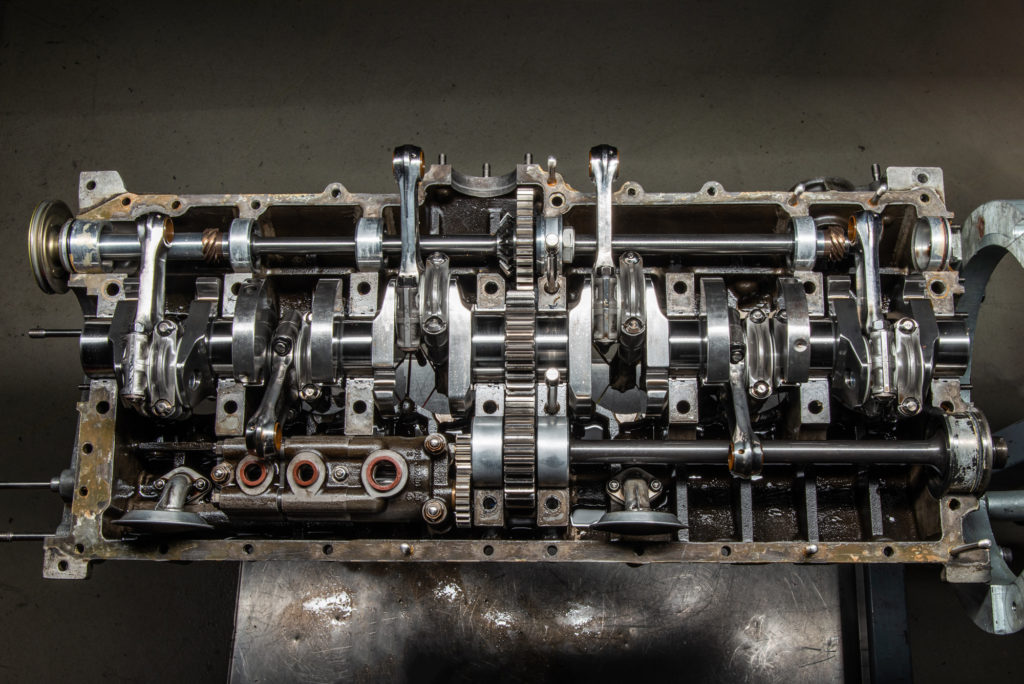

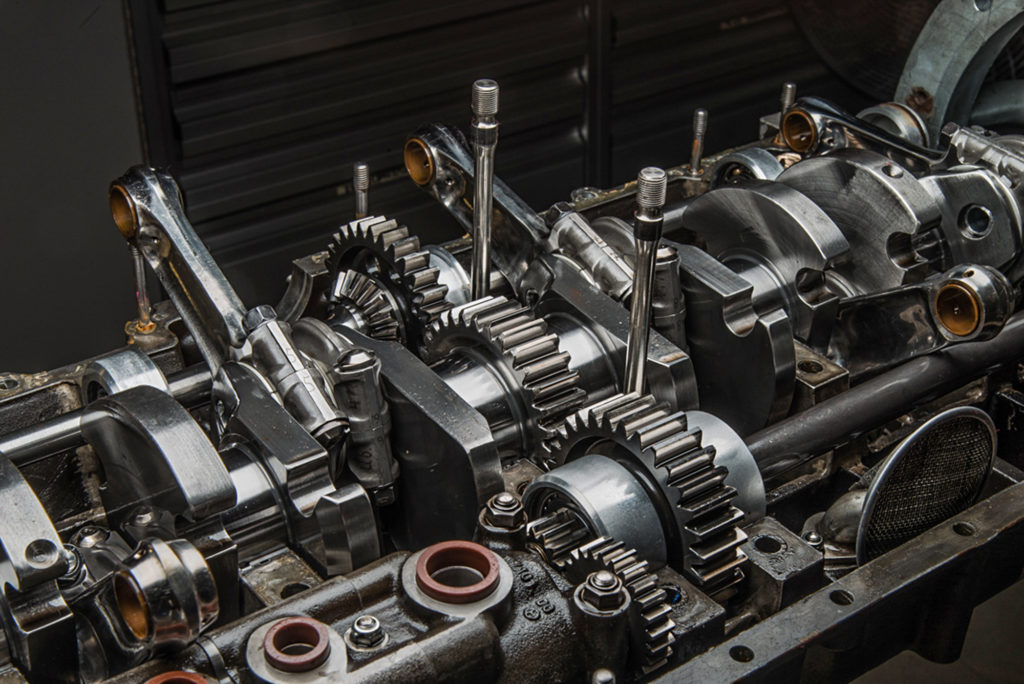

Image 3: Side angle of engine internals. This gives a better idea of the size of the gears that connect the internal components. The crankshaft is a whopping 55.6 pounds, all one piece. No bolts holding it together. The center gear was an engineering decision on that it was determined that since the crankshaft was so long that there would be too much twisting forces on the crankshaft for taking off the power at the end.

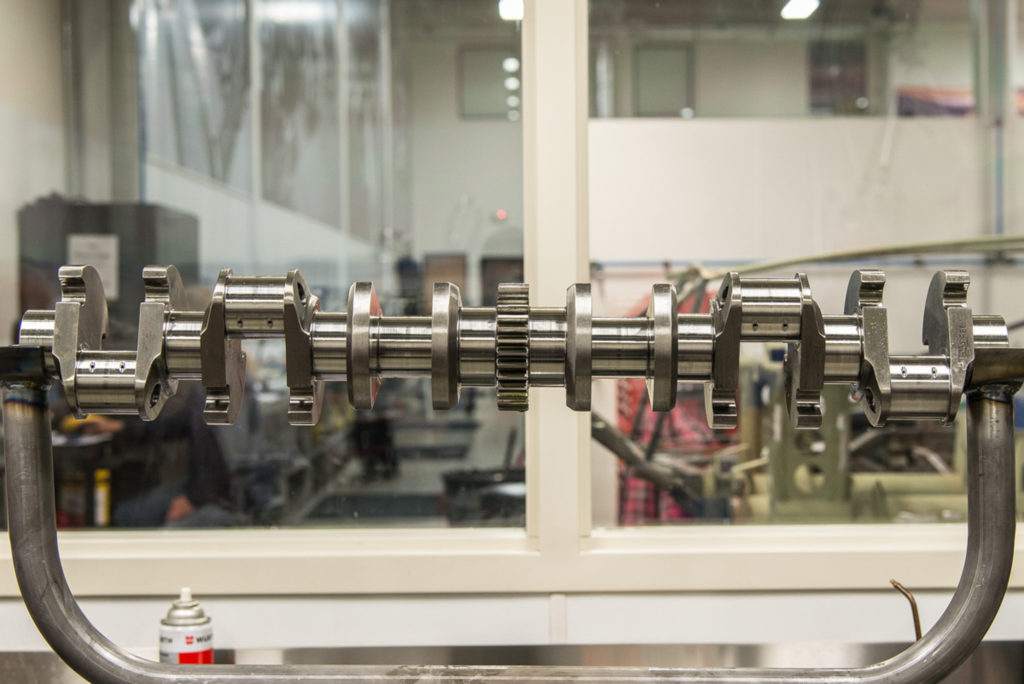

Image 4: Crankshaft part number, 912.102.031.00.

Image 5: Empty camshaft housings. These are made of magnesium.

Image 6: Porsche 917 crankshaft prominently displayed. Elevated for inspection.

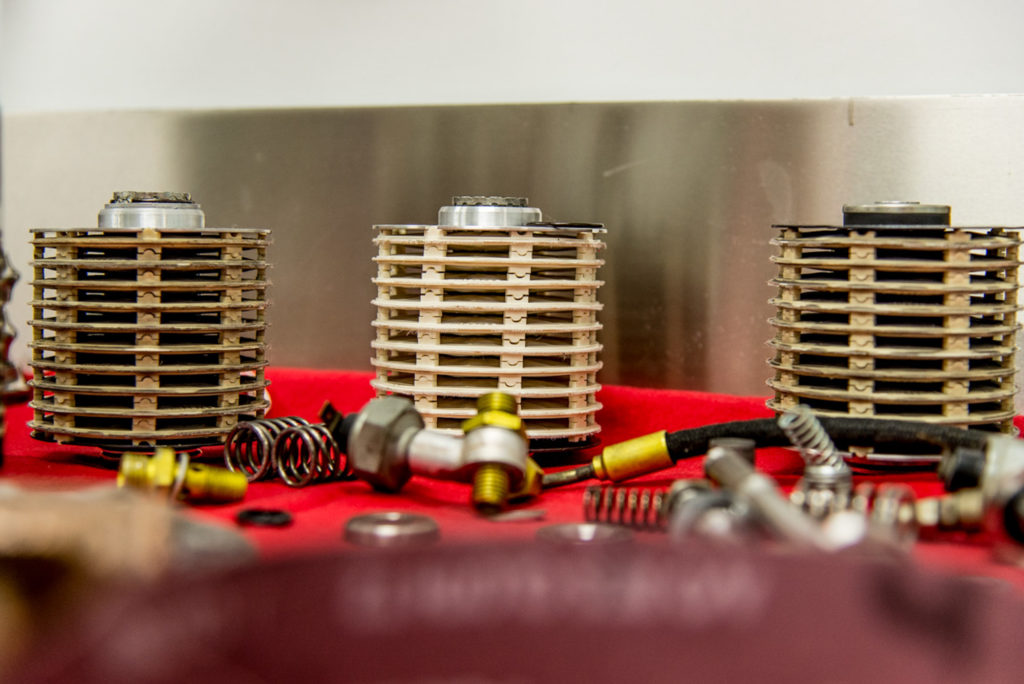

Image 7: Valves and valve springs. 24 of each!

Image 8: Titanium connecting rods. 12 for each engine. Very expensive, and very hard to find! You’ll want to make sure that you treat them well.

Image 9: Porsche 917 oil filters. 10 layers to ensure maximum oil cleaniness.

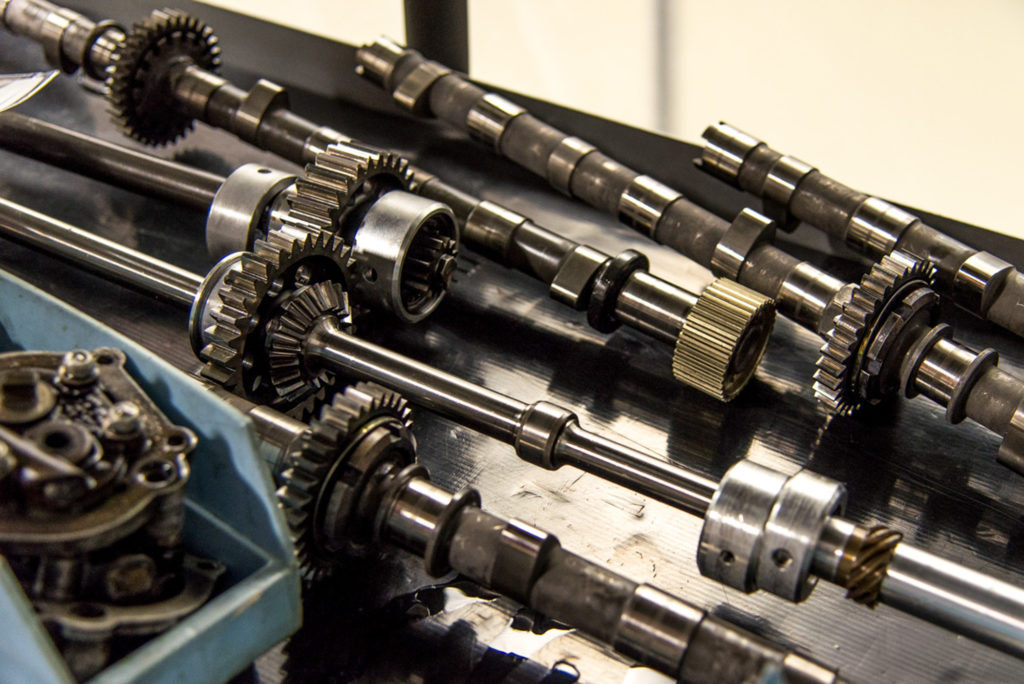

Image 10: Camshafts, upper and lower intermediate shafts removed. Notice the end of the camshaft in the middle of the image with a fine-tooth gear. This is the gear that drives the mechanical fuel injection pump.

Join us tomorrow as we’ll be posting images from putting the engine back together.

LATEST POST

- Canepa Shop Walk – Week of March 28th, 2025 March 28, 2025

- Canepa Shop Walk – Week of March 14th, 2025 March 14, 2025

- Canepa Shop Walk – Week of March 7th, 2025 March 7, 2025

- Canepa Shop Walk – Week of February 28th, 2025 February 28, 2025

- Canepa Shop Walk – Week of February 21st, 2025 February 21, 2025